Build A Sofa with Chaise Lounge

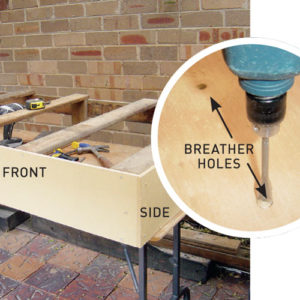

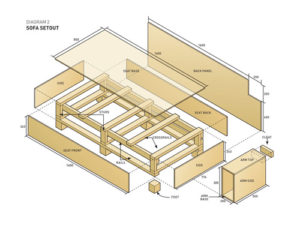

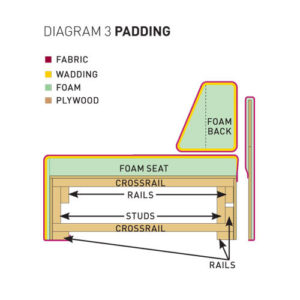

Built from pine and plywood and upholstered with foam, wadding and fabric, the sofa and chaise lounge are 800mm wide, with the cushions removed to provide a comfortable bed, while seating with the cushions is about 500mm high by 450mm wide.

DIY: $780 (Have it made for $2780)

Skill: 3/5

Time: 5 days

MATERIALS ON THE CHEAP

Many components of this lounge suite were found on council collection days, including timber for the frame, the hardwood feet and foam from old sofa cushions.

The plywood panels are packing sheets sold cheaply at the hardware store. And although the fabric was the most costly part it was still just $250, bought as remnants at 30% discount.

You’ll need to buy 6.5m of 1.5m-wide wadding, about $65, foam in various thickness, strong thread plus a needle for stitching the corners.

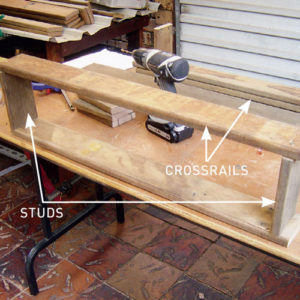

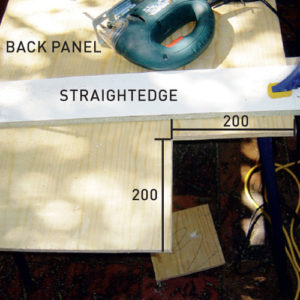

Use a sliding compound mitresaw to cut the frame and a circular saw with a straightedge to cut plywood.

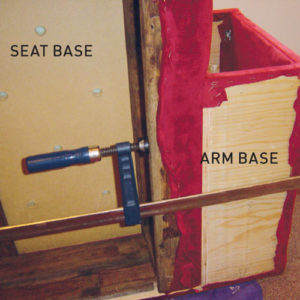

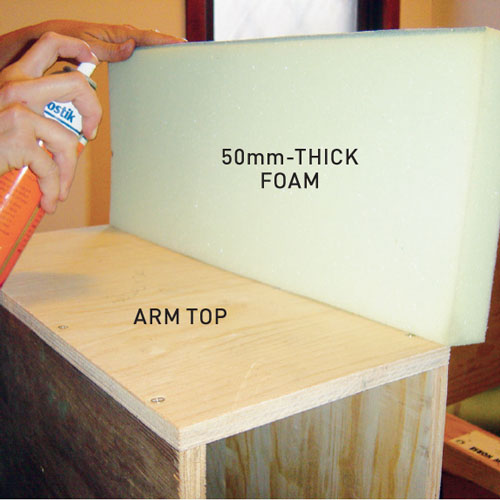

Attaching Foam

To join the two-part foam cushions and attach them to the arm, use spray adhesive on both pieces. To secure foam to the plywood seat base, apply contact adhesive to the foam using a brush and use a spatula to spread it onto the plywood. When the surfaces come into contact they stick permanently, so position the foam accurately with assistance from an extra pair of hands.

Attaching foam for extra comfort is simple.

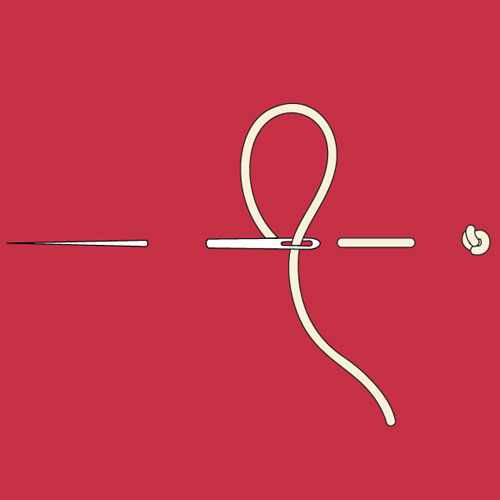

Slip Stitching Technique

Slip stitching holds a folded edge to a flat piece of fabric. Work from left to right, starting with a single thread fastened with a knot hidden inside the hem. Bring the needle out through the folded edge, pick up a few threads of the flat fabric and pierce through the fold again. Slide the needle along and out of the fold to make the next stitch.

Slip stiching is a great skill to learn for upholstering your own furniture

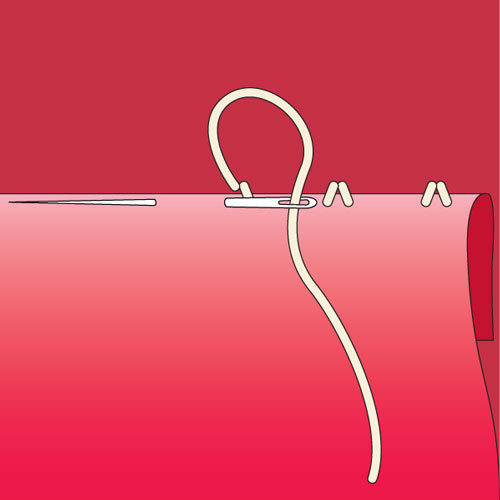

Tack Stitching Technique

Tack stiching is a great skill to learn for upholstering your own furniture

How to build a sofa with chaise lounge