Repair mortar joints

Brick is one of the most prized exteriors for homes because it’s attractive and easy to maintain. Yet over the years, water, heat and seasonal expansion and contraction all attack the solid mass of a brick wall at its most elastic (and weakest) point: the mortar joints.

Mortar joints deteriorate wherever water can soak them – under windows and walls, around chimneys, behind downpipes, at ground level and at any exposed wall top.

Repairing eroding and cracked mortar joints is called pointing, repointing or tuckpointing. We’ll show you the proper tools and techniques to repair and restore cracked and worn-away mortar joints to make them solid, durable and good looking. To keep them that way for the long run, you have to stop water from getting into your bricks and foundation.

Repointing brick is slow, painstaking work that requires few special skills but a lot of patience. Using the steps we show, you can expect to repoint about two square metres. of brick work a day. However, if you rush and do careless work on a highly visible area, the repointing brickwork will stick out like graffiti. Brick is durable; bad results will bother you for a long time! If you don’t have repointing brick experience, consider hiring a pro for:

Larger-scale pointing jobs, such as a whole wall that needs repair.

Chimney and wall repair requiring setting up and moving scaffolding.

Areas with a lot of loose or missing brick requiring rebuilding walls or corners.

Colour-matching new mortar to existing mortar in highly visible areas.

Read on to learn how to repoint brick.

Tools Required

Angle grinder

Dust mask

Flat chisel

Hammer

Rubber gloves

Safety glasses

Trowel

Tuckpointing tool

Whisk broom

Materials Required

Mortar mix

Step 1: Use an angle grinder for larger, harder repointing brick jobs

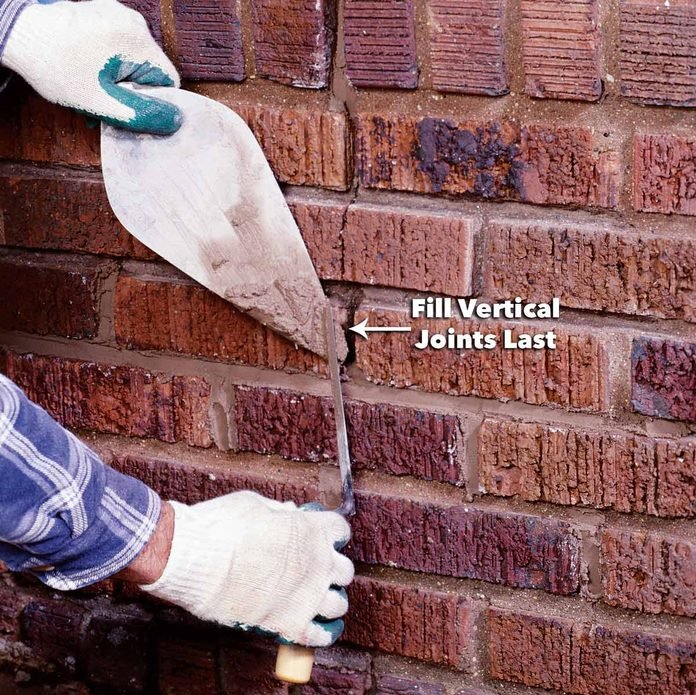

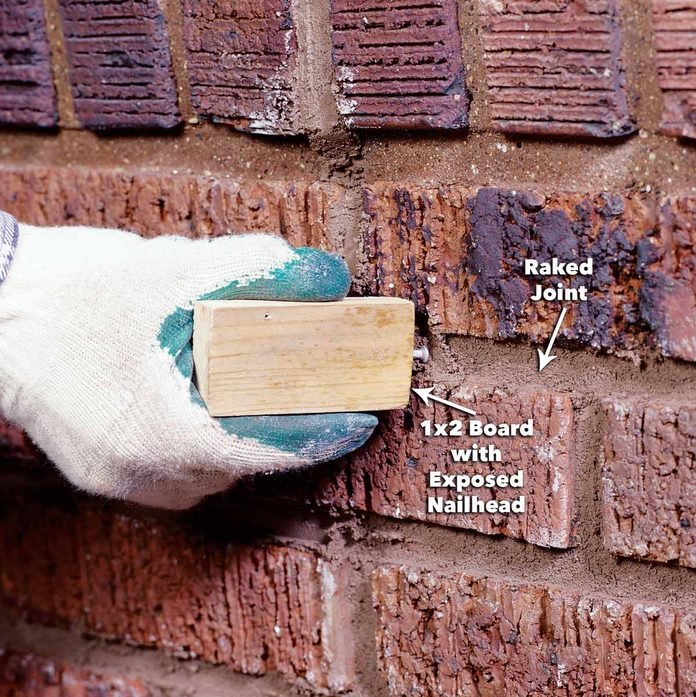

Cleaning out old mortar joints requires basic tools: hammer, flat utility chisel, safety glasses, dust mask and whisk broom. Filling the cleaned-out joints requires masonry tools: brick trowel, 10mm pointing trowel, a special tool for contouring the joints and waterproof gloves.

If you do tackle larger jobs or encounter hard mortar that can’t be easily chiselled out, we recommend that you rent or buy an angle grinder fitted with a diamond blade. Select a grinder with a 115mm blade diameter; larger grinders are harder to control and cut the mortar too deep. To begin, cut grooves 20-25mm deep in cracked or deteriorating mortar using a 115mm angle grinder fitted with a diamond blade. Push the blade into the joint until the grinder head contacts the brick, and make a single pass along the centre of the joints.

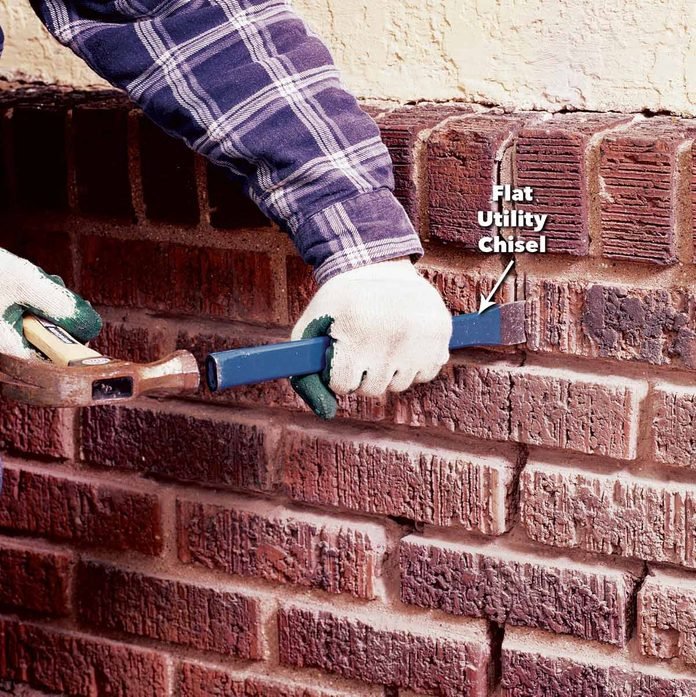

Step 2: Chip out loose mortar

Break out old mortar using a hammer and cold chisel or a flat utility chisel that’s narrow enough to fit into the joints. Position a flat utility chisel at the edge of the brick and drive it toward the relief cut to fracture and remove the mortar. Wear safety glasses and a dust mask and remove 20-25mm of old mortar (more if needed) until you reach a solid base for bonding the new mortar. If the mortar is so soft that the bricks are loosening up, you’ll have to remove and properly reset them. If the cracked mortar is harder, make a relief cut down the centre of the mortar joint using the pointed edge of the chisel and then gently chip out the mortar (brick grout) that contacts the brick.

If the removal work is going really slowly, use an angle grinder to make the relief cuts. Exercise care here; the grinder can easily nick and chip the bricks, so don’t use it to clean out the mortar contacting the brick. To avoid nicking the bricks, cut the vertical joints before cutting the horizontal joints.

DIY Basics: Check out our essential guide to grinders, files and rasps.