Pocket Hole Workbench

Use a simple but effective joinery system to build a solid bench from pine and plywood.

No workshop is complete without a sturdy and stable bench, but using fasteners such as bolts for assembly doesn’t result in the most streamlined finish.

This workbench is built using simple butt joints for the frame that are secured with the Kreg system of angled pocket holes and screws.

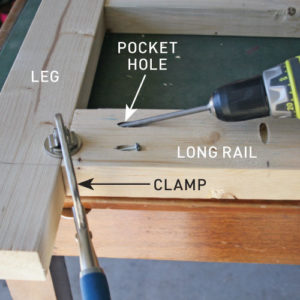

Pocket hole screws act like internal clamps, ensuring strong joints for a tough, durable workbench.

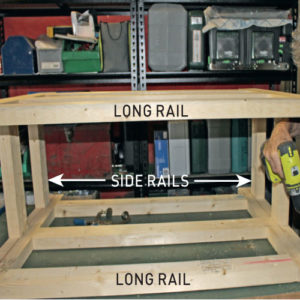

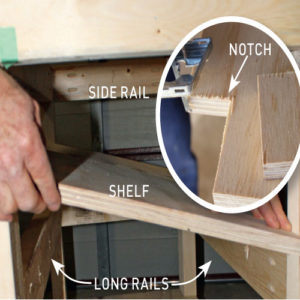

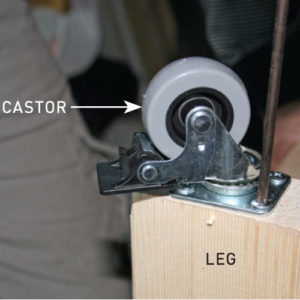

Assemble the frame from pine, add a plywood top and shelves then trim the edges, finishing the bench with two coats of clear polyurethane and castors for mobility.

To mark up the frame parts quickly and precisely, use the first leg and rail as a template for the remaining pieces, ensuring the frame butts together squarely and is easy to assemble.

Use a mitresaw to cut the pine, and a circular saw with a straightedge guide to cut the plywood, or have it cut by the supplier for a small fee.

Easy joinery

Joinery using dowels and biscuits requires accurate measuring and alignment of mating workpieces.

It can be time-consuming and specialised tools may be needed for cutting the recesses for the fasteners.

Pocket hole joinery is a quick and easy concealed fastening system that can also be used to edge-laminate boards without needing to drill or cut slots in both workpieces.

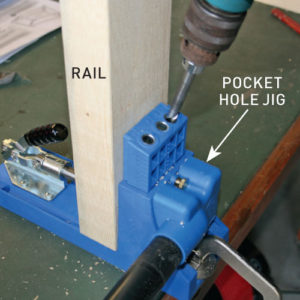

To make a joint, drill a hole at a 15º angle into one workpiece using a purpose-designed stepped drill bit, then join it to the second one with self-tapping screws.

Adhesive is usually not required, but adding it can result in a joint that is even stronger than a traditional mortise and tenon.

The core components of the Kreg system include a drilling jig, stepped drill bit and pocket hole screws.